OVERVIEW

Stamping out downtime with magnetic precision and power.

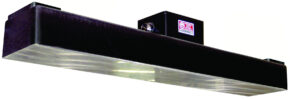

Reliable magnetic solutions that boost production efficiency and protect assets from damage, all while saving you working space.

To address challenges in the stamping sector, manufacturers and businesses depend on tools built into their operational processes that are designed for their needs. Industrial Magnetics’ tools are a valuable investment that ensure long-term profitability.

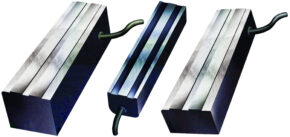

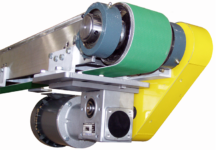

Equipment wear is a significant issue due to the repetitive and high-pressure nature of stamping operations, which gradually degrades machinery components. The separation of sticky and oily parts can also lead to damage and double-blanking. Furthermore, space constraints present another obstacle for stamping companies, given that the machinery, equipment, and storage demand for stamping operations often demand significant floor space. These challenges impact operational efficiency, productivity, and overall success.

Stamping tools from IMI mitigate equipment wear by capturing metal debris, preventing damage from sticky and oily parts with magnetic separators, and optimizing space with compact magnetic solutions, enhancing operational efficiency and productivity.