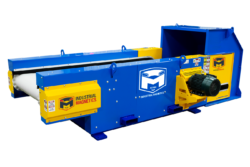

Eddy Current Separators

Our Eddy Current Separators are designed from the ground up to provide high recovery rates (97%+) and low operating costs. Eddy Current Separators are ideal for a range of applications, including: MRF (Material Recovery Facility), C&D, Incineration, Auto Shredding, Electronics Recycling, and more.

OVERVIEW

Our Eddy Current Separators are designed from the ground up to provide high recovery rates (97%+) and low operating costs. They are ideal for a range of applications, including: MRF (Material Recovery Facilities), C&D, Incineration, Auto Shredding, Electronics Recycling, and more. The units vary essentially in one area, the number of poles. While all of our units do a remarkable job on UBC (Beverage Can) recovery, the standard 8-pole unit was designed just for this job. The 16 pole unit was initially designed for glass clean-up, though it excels in any application where recovery of smaller particles is required.

The Throw Makes The Difference™ - Every ECS machine is built with the highest quality materials and to an unmatched quality standard. They have the strongest and deepest field in the industry, for a farther throw and a higher and cleaner UBC recovery rate. The ECS is in use at major MRFs around the world with excellent results. Though we talk of 97% recovery most of our units have to pass more stringent compliance tests. No matter what your volume the Eddy Current Separator will add to your bottom line.

Benefits

FEATURES

- Eccentric set rotor for maximum strength (highest gauss in the industry)

- High-grade rare earth magnets

- Stainless steel sleeve on all rotors

- Removable service panels for easy maintenance

- Variable speed motor for rotor and belt

- Carbon fiber shell minimizes ferrous burnout

- Internal motorized drive drum for a more compact design

- Low profile design (easy retrofit)

- Take up screw adjustment for easy belt tensioning and tracking

- Heavy-duty construction

- Lifting eyes for easy installation

- Durable powder-coated frame (available in custom RAL colors)

- Urethane belt with corrugated sidewalls

- Durable brushes and guards to prevent material migration

- Cantilever design for one-piece belt change

- +/- 1% of our throws in your clean aluminum

OPTIONS

- Skid mounded unit available

- Mobile unit designs available

- Control packages

- Vibratory feeders

- Units built to accommodate virtually any height requirement

- Total system design

- Rotational speeds up to 3600 RPM

- Optional splitter hood comes with adjustable side closures and an adjustable divider vane - Specialized controls are available

- Extended placement of splitter vane

Applications

More products for Eddy Current Products

I'd like to speak to a magnetics expert

Have questions you’d like to speak to an IMI team member about? Fill out the contact form with the information you have, and a member of our sales team will be in touch soon. We can’t wait to chat.