Milling Chucks

You are sure to find the exact magnetic chuck for the milling operations in your industry and your business among our high-quality milling chucks. We offer an electro-permanent magnetic chuck and a permanent magnetic chuck to encompass all your milling operations.

OVERVIEW

NEOMILL™

These permanent magnetic chucks are designed using neodymium magnets for milling applications. The dual neodymium magnet pack generates an exceptionally high holding force on workpieces with an uneven or rough contact surface.

- Double neodymium magnet pack generates a powerful holding force on workpieces with an uneven or rough surface

- Low magnetic field, concentrated over the top plate without stray fields. No chip contamination of the workpiece surface and cutting tool

- Transverse, close pole division 11 mm of steel and 4 mm of brass allows optimal holding of workpieces only 26 mm long and 6 mm thick. The top plate can be drilled and tapped to accommodate pins, pegs, or other clamping aids

- Vibrations are dampened, contributing to machining accuracy

- Nominal holding force: 174 lb/in²

- Usable top plate life: 5 mm

- Supplied with Allen key, set of clamps, and manual

- Ideal for milling small to large workpieces

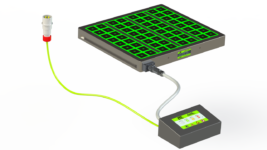

TURBOMILL™

Walker Turbomill MMC Magnetic Milling Chucks eliminate the use of traditional clamping methods in CNC machining centers and include tombstone applications. You don’t need clamps or fixtures of any type. The applications shown in this demonstration are Profiling, Face Milling, Plunge Milling, Slotting, Drilling, and Edge Milling.

The Turbomill differs from other electro-permanent systems through its unique conception, which favors a maximal flux concentration.

A very strong attraction of more than 241 lb/in² is reached.

- Electro permanent magnetic chuck, (ALNiCo and neodymium)

- Reduce set-up time and increase available machine time

- Help to dampen vibrations, resulting in longer tool life

- Allow single set-up machining with 5-sided accessibility

- Operation through TM Series controls

- Through drilling possible with the use of rise blocks

- Backrest and end stops

- Hold down clamps

- Cable for the current supply of the chuck: 10 ft

Milling Chucks Products

| SKU | Weight | Brass Width | Clamp Slot | Face Height | Face Size | Overall Length | Overall Width | Pole Width | Style | In Stock |

|---|---|---|---|---|---|---|---|---|---|---|

Switch to product variant SKU CP0612MIL Switch to product variant SKU CP0612MIL | 45 | 0.157 | 0.43 x 0.47 | 2.2 | 6x12 | 12.31 | 6.63 | 0.433 | MILLING | |

Switch to product variant SKU CP0618MIL Switch to product variant SKU CP0618MIL | 77 | 0.157 | 0.43 x 0.47 | 2.2 | 6x18 | 18.31 | 6.63 | 0.433 | MILLING | |

Switch to product variant SKU CP0818MIL Switch to product variant SKU CP0818MIL | 110 | 0.157 | 0.43 x 0.47 | 2.2 | 8x18 | 18.31 | 8.63 | 0.433 | MILLING | |

| Switch to product variant SKU CP1224MIL | 196 | 0.157 | 0.43 x 0.47 | 2.5 | 12x24 | 24.31 | 12.63 | 0.433 | MILLING |

Downloads

More products for Magnetic Chucks

I'd like to speak to a magnetics expert

Have questions you’d like to speak to an IMI team member about? Fill out the contact form with the information you have, and a member of our sales team will be in touch soon. We can’t wait to chat.