FXL1515P5CT401Flaig Electromagnet Chucks

Flaig FXL Magnetic chucks are used by fabricators who want to securely hold their steel workpieces while they grind or mill without damage that can come from common mechanical clamping and other chuck devices.

Product image not available.

OVERVIEW

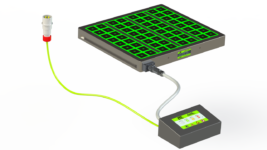

FXL Electro-Permanent Magnetic Workholding Chucks

The FXL square pole technology is the result of over 20 years of experience in magnetic clamping technology and combines solutions to the most common customer requirements with the highest quality design.

Magnetic poles, fed by AlNiCo and NdFeB magnets, are anchored in a solid, super-stiff monobloc body by means of a tool steel insert with M8 internal thread. The back of the clamping plate remains flat and can be drilled in at all points - for example, for inserting a zero-point clamping system. For this purpose, the magnet system is coated with high-performance resin in a multi-stage process, which has a high mechanical strength and ensures absolute tightness and perfect electrical insulation.

Clamping slots and transport threads help to quickly attach and fix the magnetic clamping plates; the connection is made via the proven 28mm 4-pin plug connection or also via fixed connection sockets.

FXL magnetic clamping plates can be controlled with our FXL-C control units or with almost all control units from other leading manufacturers.

For our FXL magnetic clamping systems, which are manufactured in Germany, we use only materials of the highest quality.

Various pole sizes and geometries are available. Depending on the chuck series model and the expected workpiece geometry, you can choose between 50mm series square poles, 70mm series square poles or even radial poles.

Reliable: Electro-permanent magnetic clamping technology requires the connection to the control unit only for clamping and unclamping, the cable can be disconnected during machining.

Ideal for palletizing, for rotating clamping plates or even just to be able to close the machine door.

Clever: With little effort, it is possible to convert on site from a plug-in connection to a fixed connection or vice versa. In this way, a flexible clamping plate can quickly be converted into a fixed clamping plate with maximum availability if requirements or machinery change.

Note: the plug-in connection with closed cover achieves protection class IP67 the fixed connection achieves protection class IP68, tight up to 5 bar the connection is made via spring clips - quick and safe

Informative: The optionally available switching status display informs the user about the switching status of the clamping plate even when the cable is disconnected; ideal for palletizing.

FXL-50 Series Electro-Permanent Magnetic Clamping Systems

FXL magnetic chucks, with the 50mm pole type, are used to securely clamp workpieces from approximately 100x100mm with low material thickness.

Poles of size 50x50mm generate a magnetic field that penetrates approximately 12mm into the workpiece, which is why they are particularly suitable for thinner and smaller workpieces. Another advantage is that, especially with smaller workpieces, more pole transitions are occupied, which ensures more even clamping. The nominal holding force is a super strong 160 N/cm2 = 4kN per pole.

FXL-70 Series Electro-Permanent Magnetic Clamping Systems

FXL magnetic chucks, with the 70mm pole type, are used to securely clamp workpieces from approx. 150x150mm with material thicknesses from approximately 15mm.

Poles of size 70x70mm generate a magnetic field that penetrates approx. 18mm into the workpiece, which is why they are particularly suitable for larger workpieces.

A very good air gap behavior also allows uneven workpieces to be clamped securely. In addition, pole extensions with a larger stroke can be used on 70mm poles for height compensation. The nominal holding force is a super strong 160 N/cm2 = 7.8kN per pole.

Benefits

- Low-vibration machining and clamping of workpieces

- Fast and safe clamping of uneven parts

- Uniform clamping force over the entire surface without distorting or crushing the workpiece

- Five-sided machining in only one setup

- Full usability of the traverse paths

- Minimal set-up times

- Fast and accurate plane-parallel milling

- Clamping of warped welded constructions in the shortest possible time

- Fast assembly of individual, magnetic clamping devices

- Same holding force in all directions due to square pole technology

Applications

More products for Magnetic Chucks

I'd like to speak to a magnetics expert

Have questions you’d like to speak to an IMI team member about? Fill out the contact form with the information you have, and a member of our sales team will be in touch soon. We can’t wait to chat.